Optical System Design

Imaging

- Imaging optics vary in size and complexity. I have worked with 1-2mm optics to 150mm optics, from simple singlets to multi-element projection lenses. Though each design can be quite different from the other, with sound optical design fundamentals, each system can be designed efficiently and accurately.

- Imaging optics are used in a variety of industries: consumer products, industrial equipment applications, medical, automotive, military and government-funded projects. And who knows? They could yet be used in industries no one has yet tried.

Non-Imaging

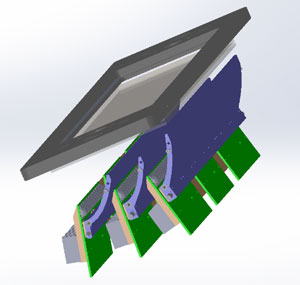

- Non-imaging optics redirect light from the source to the area or point of interest. I have worked with a variety of non-imaging optics such as diffusers, light pipes, fiber optics and solar concentrators.

- Non-imaging optics can have widely varying design specifications. I have worked on several

non-imaging projects like color measurement tools, high efficiency solar concentrators, projection lens illumination and material scanning illumination giving me the experience to design for your needs.

non-imaging projects like color measurement tools, high efficiency solar concentrators, projection lens illumination and material scanning illumination giving me the experience to design for your needs.

Opto-Mechanical Design

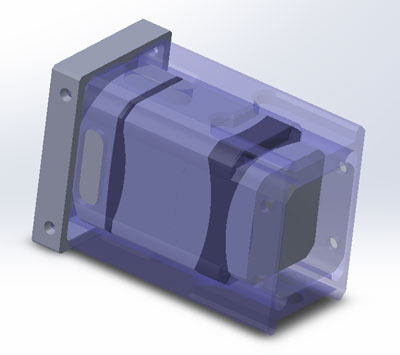

System Opto-Mechanics

- Optical mounting is key to a consistent optical system design. I have had experience with a variety of mounting techniques giving me the ability to choose the right method for your system.

Coupled optical to opto-mechanical system designing allow for fast and reliable product development. This combined design knowledge gives me an advantage and the needed insight to know how to make even the most challenging projects successful.

Coupled optical to opto-mechanical system designing allow for fast and reliable product development. This combined design knowledge gives me an advantage and the needed insight to know how to make even the most challenging projects successful.

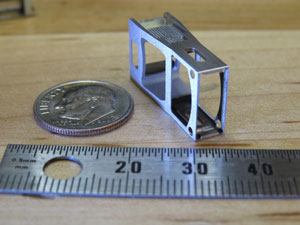

Component Assembly

- Optical assembly is done most effectively when the assembly process is considered from the very beginning of the design process.

- Optics handling and cleaning must also be considered when working with optical assembly. Small and odd-shaped optics often present problems when it comes to handling and cleaning. Knowing the tooling options and methods makes this step simpler.

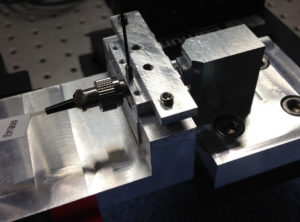

Component Alignment

- Correctly aligned components allow for the designed optical performance to be realized. I incorporate testing steps to be able to verify that the proper alignment is achieved.

- Component alignment techniques often depend on the space available, the volume produced and the cost targets of the system. I have working experience with many different alignment techniques: auto collimators for arc second tilt adjustments, differential micrometers for micron-level position adjustments and microscope-camera systems for image-driven adjustments.

Tooling Design

- Proper optic system assembly is aided by proper tooling. My experience with a large number of alignment systems, helps me design the right tooling set for your application.

- Understanding system function and tolerances can allow for better tooling placement and design. Practical knowledge of tooling performance aids me in making the right tooling decisions.

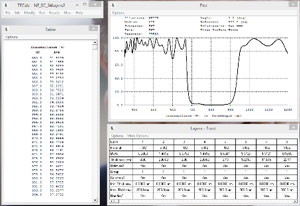

Color/Spectral Measurement Tool Development

- Spectrometers to color sensors to densitometers, I have worked on all of them.

Thin Film Design

- Bandpass filters, anti-reflection filters, high reflectance dichroic filters and more can be designed at Clark Optical Consulting and Prototyping, LLC.

Optical System Alignment and Assembly Process Development

- Working on system alignment and assembly can be challenging, but aided by proper optical system design and opto-mechanical design, this process can proceed much faster and keep assembly time and costs to a minimum.

Prototyping

Assembly

- Having a functional prototype can be invaluable to provide feasibility and initial/expected performance marks. I can help you make the right prototype design to get the needed information quickly.

Vendor Management

- Many optical systems require components across multiple disciplines, and thus need to be effectively integrated to make the system work. I have the knowledge and contacts to get the right parts for the job.

Transition Help from Proto to Manufacturing

- When the prototype design meets the program needs, a manufacturing design will be needed. I can help my clients design their products for manufacturing, or help lead this effect at another contract manufacturer of your choice. I understand the process and can get the job done for you.